Very Early Smoke Detection System

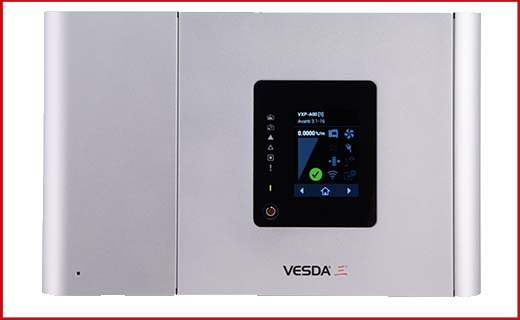

VESDA Smoke Detection System is a Very Early Warning Aspirating Smoke Detection System

VESDA Smoke detection systems are very useful for fire protection solutions in large scale buildings. VESDA (an abbreviation of Very Early Smoke Detection Apparatus) is a Very Early Warning Aspirating Smoke Detection solution. With continuous air sampling VESDA very early warning smoke detectors provide the earliest possible warning of a potential fire giving you with precious time to investigate, intervene and avoid business disruption, in addition to the damage, downtime and cost of a suppression release.

Working Principle of VESDA Systems

The air is drawn into the piping network by a high-efficiency aspirator. The VESDA system consists of a dual-stage filter. During the first stage of filtering, it removes all dirt and dust from the air when it reaches the detection chamber. The second ultrafine stage filter provides additional clean air to the optical surfaces of the detector. After the filtering is done the air will enter the laser detection chamber and it gets exposed to the laser source. When a cloud of smoke enters, light is scattered in the detection chamber and it is detected by the receiver system. The VESDA detectors use a Building management system(BMS) to pass the information to the fire alarm control panel. For this communication relays or high-level interface is used. These things can be analyzed only by a qualified professional having sound knowledge in the detection and building management systems.

The companies are preferring qualified engineers and technicians who can handle all the modern-day challenges. Most of the Training centers provide hands-on training in BMS and other modern detection systems.

There are wide varieties of VESDA smoke detection devices available according to the area it is used. Almost all VESDA products identify smoke at an early stage and continue to sample air from all sectors to monitor fire growth. VESDA provides four levels of alarm which are classified as alert, action, fire 1 & fire 2.

Principles Of Aspirating Sample Detection

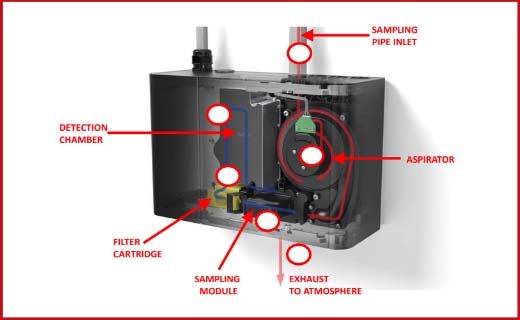

A central detection unit in the aspirating smoke detection system, which helps to bring air from the pipes and detects smoke.

The aspirating detector consists of

- Sampling pipe network which can gather air through sampling holes and send it to the detector.

- Aspirating smoke detector: It consists of a sensing chamber having a highly sensitive sensor to detect even the micro smoke particle. A fan is installed to draw air from a protected area to the sensing chamber.

- Optical fiber to remove large particles from entering the sensing chamber.

- Exhaust pipe to remove the sampled air from the detector.

Sampling holes are holes made in the piping network to draw air and send it to ASD.

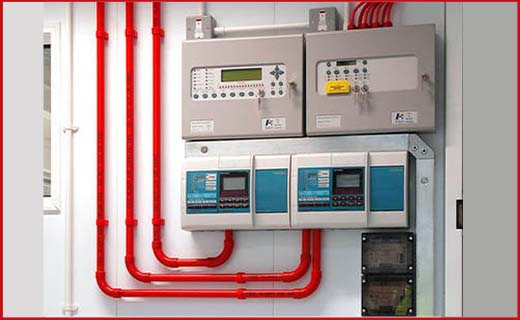

Aspirating Detection System Piping

The Aspirating smoke detector is connected with a sampling piping network through the port from the top or bottom. The piping network should be of single or multiple pipe configuration. The sampling pipes can be installed horizontally above the ceiling level. The pipes are kept in void space with capillary tubes. The pipes consist of small holes through which air can be drawn into the pipe. Sampling holes are spaced according to the design software. The most common pipe used is 25 mm dia made of Pvc, Upvc, and Cpvc.

Pipes made from copper and other non -ferrous materials also can be used. The pipe diameters can vary according to the local codes and regulations. Pipes are usually connected using ABS glue and unions should be used in areas where future disconnection is needed. A specialized T joint should be used to provide a capillary tube and a sampling point. Pipe ends are provided with end caps having a central hole to control air. For pipes having fewer sampling holes, end caps can be considered as sampling points. The fittings are made of the same material as pipes. Proper hanger supports should be provided for the pipes. The piping team needs to make sure that there will be no holes near the bends. The installation of pipes should be done by well-qualified pipe fabricators. There is a high demand for trained fabricators in India and abroad.

Aspirating Smoke Detector

Aspirating smoke detection systems can be classified according to the type of detection technology

- Laser-based systems (filtered): This system works on laser technology. The air passes through the filter to remove all large particles and the filtered air passes in front of the laser. A photo collector is used to sense the light scatter caused by smoke. The detectors can analyze the quality of smoke detectors.

- Non-filtered laser-based systems: This method purely uses a laser detection system. Here the air is passed to the sensing chamber without passing through the filter. The photo collector counts the number of micro air particles and it can differentiate between dust particles and smoke particles.

- Cloud chamber: The Cloud chamber system is one of the oldest sensing technologies. Here the sensing element inside a sealed chamber. The sealed chamber is filled up with high dense water vapor. Once the interaction takes place between smoked particles and vapor, the area gets ionized. This will result in a condensation process around a nucleus. The particles change their size from below the wavelength of light to a size above the wavelength of light. The particles are sized properly and the photocell can detect the mist/dust particles.

- Dual Source Sensor: This consists of a Blue LED to detect smoke particles which are very low in concentration and infrared lasers to check for dust particles and eliminate false alarms. The inbuilt advanced algorithm interprets signals and distinguishes between smoke and dust particles.

Aspirating Smoke Detector Exhaust Systems

In a normal operating cycle, the pressure in the air pressure-protected space should be the same as the air pressure in the space where ASD is mounted. If the air pressure in the exhaust space is more than the pressure in the protected space, this will result in resistance to the flow and drag on the fan. In this case, the fan runs at a slower speed and increases the transporting time for the air to reach the sensing chamber. The sensing chamber is designed to detect the smoke particles moving through the fan. To eliminate the pressure difference the piping exhaust system must be located in the same room where sampling takes place. Exhaust works need proper supervision. A trained technician is compulsory in doing exhaust works in critical areas.

Transport time is the actual time required for smoke particles to travel from the sampling point to the ASD.

Aspirating Smoke Detectors Sampling Methods

There are five sampling methods used

1. Primary Sampling

The primary sampling method is mainly configured to sample the air where the flow is more. For areas having a high airflow, the sampling location is at return grills, air handling units, or in return air ducts.

2. Secondary Sampling

The secondary sampling requires holes in the ceiling level to check the airflow. The hole spacings are done as per standard.

3. Localised Sampling

These sampling techniques are used in open space. It is used in rack sampling systems in open warehouses.

4. In-Duct Sampling

In-Duct Sampling, Conventional duct attached smoke detector system replaced with an ASD to close down the AHU’S and fire dampers during the time of the fire. It can be used to detect exhausted smoke particles.

5. In-Cabinet Sampling

This sampling system uses air sampling holes to monitor specific equipment in an open space. The volume of concentration is less in this type of sampling. The ASD monitors the air used in equipment cooling.

ASD monitoring systems should be analyzed and reviewed by well-trained engineers. They should have a piece of sound knowledge in smoke detection systems.

ADS System Consideration In Relation With Operating Principles

-

Dilution Effect

The main factors affecting the sensitivity of ASD systems are the number of sampling holes drilled in the piping network and smoke detection thresholds. The dilution of the air coming into the sensing chamber depends on the number of sampling holes drilled in the piping network. When a cloud of smoke is drawn into a single sample hole which results in the dilution of smoke concentration due to the passage of smoke through other sampling holes aspirating clean air. When the volume of clean air is mixed with smoke-filled air in the detection chamber the smoke-filled air is diluted. When the smoke is transported through the pipe, it combines with clear air, thus diluting the smoke density. The dilution effect is directly linked with the number of sampling holes in the piping network. The more sampling holes, the more volume of air is sent to ASD and that results in dilution of smoke in the air.

While setting an alarm for the smoke detection system, the dilution effect needs to be considered. Experimentation is done by creating a smoke near one of the sampling holes. The same amount of air will be let in through all the sampling holes. At the one end of the pipe, there is a smoke source, which prevents any other smoke to enter in any of the sampling holes. The smoke passes each of the sampling holes and it gets mixed up with clear air and once the smoke reaches the detector it will be of 1/10th the starting density. Issues that are affecting the dilution effect is the number of sampling holes, the number of bends, elbows, and fittings used in the piping system.

2. Transport time

The transport time is the time taken for the smoke to reach the sensing chamber. The time measured in seconds for the particles to reach the sensing chamber from the sensing point. When discussing transport times, various factors are taken into consideration.

- Number of sampling holes

- The aspirator speed setting (rpm)

- Sensitivity setting of the detector

- Total qty of sampling pipe.

Benefits Of Aspiration Detection Systems

ADS detection has a wide range of benefits

- Early levels of smoke detection

- Reliable detection

- Working at high airflows

- Usage in demanding environments

- Not subjected to tampering

- Easy maintenance

Briefly, VESDA plays an important role in fire alarm systems, this article made an attempt to create an awareness of Aspiration Detection Systems. Hope you got an idea after reading the blog until the end.